Product Details

Molybdenum Wire (HS Code: 81029600)

Specification:

| Material | Process Method | Size | Applications | Code | |||||||

| Pure Molybdenum or Doped Molybdenum |

Heat-Drawing or Cold-Drawing |

0.04~1.00mm | Mandrels for coiled tungsten filament,or anchors for incandescent light,etc… | ① | |||||||

| 1.00~3.00mm | For heating of electric furnace,or sealing metals | ② | |||||||||

| 0.10~0.24mm | Used in electronic spark cutting | ③ | |||||||||

| 1.45~3.20mm | For metal spraying | ④ | |||||||||

| 0.30~2.40mm | Used for drawing smaller size | ⑤ | |||||||||

Chemical Values (%):

| Grade | Mo content | Total impurity | Every impurity | Doping element | |||||||

| Mo1 | ≥99.93 | ≤0.07 | ≤0.01 | -- | |||||||

| Mo2 | ≥99.9 | ≤0.1 | ≤0.01 | -- | |||||||

| Mo3 | ≥99.73 | ≤0.07 | ≤0.01 | 0.01-0.20 | |||||||

Size and Tolerance:

| Application | Size | Tolerance | |||||||||

| Application ① | 0.04~1.00mm | For mandrels wire +/- 1% | |||||||||

| For anchors wire +/- 2% | |||||||||||

| Application ② | 1.00~3.00mm | +/- 0.02mm | |||||||||

| Application ③ | 0.10~0.24mm | +/- 0.003mm | |||||||||

| Application ④ | 1.45~3.20mm | +/- 0.02mm | |||||||||

| Application ⑤ | 0.30~2.40mm | +/- 2.0% | |||||||||

Deliver Status:

| Code | As Drawn | Burning-hydrogen | Electrolytic Polishing | Straightened | Cutting | ||||||

| DS-01 | ● | ||||||||||

| DS-02 | ● | ● | |||||||||

| DS-03 | ● | ||||||||||

| DS-04 | ● | ● | |||||||||

| DS-05 | ● | ● | ● | ||||||||

| Surface Finish | Surface is spread graphite milk and shows uniform black color. It shows metal luster when clean graphite. Free of overlaps, splits,cracks and visual contamination which would be a disadvantage in further processing, severity oxidation and mildew isn't all | ||||||||||

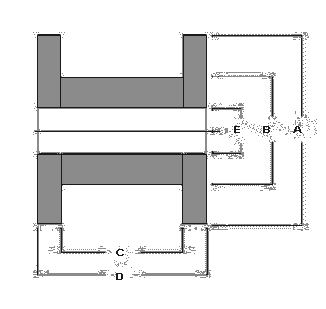

Available Materials and Sizes for Spools (Unit: mm):

| Material | Specifications(mm.) | Weight | |||||

| A | B | C | D | E | |||

| Flange Dia |

Spool Dia |

Traverse Width |

Overall Width |

Shaft Dia |

Gram | ||

| NO.1 Plastic Spool(Large) | 130 | 100 | 70 | 80 | 25 | 270 | |

| NO.2 Plastic Spool(Small) | 54 | 37 | 24 | 31 | 10 | 31.2 | |

TOP